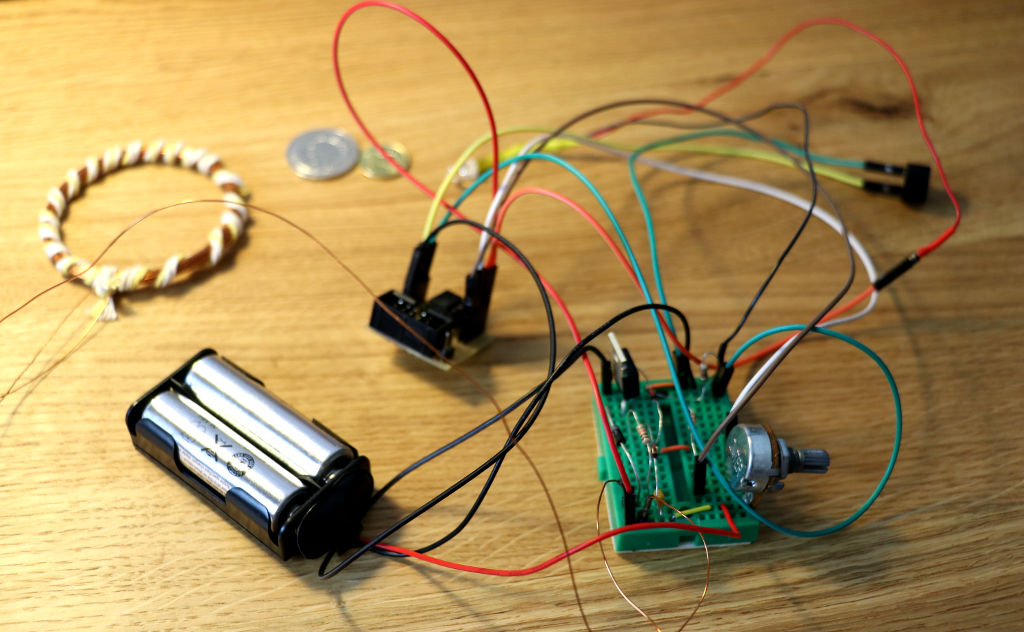

This experimental project shows how to build a simple PI (Pulse Induction) metal detector based on ATtiny13 / AVR microcontroller. My goals were to make a circuit as simple as possible and to use only popular / cheap electronic parts. The device has been tested with very small coil (55mm diameter, about 30 turns of 0.5 DNE) and only 3V power supply. It’s my first design of PI metal detector and I’m really happy with the results! The prototype was able to detect little coins (6cm distance) and wires in the wall. The code is on Github, here.

How It Works?

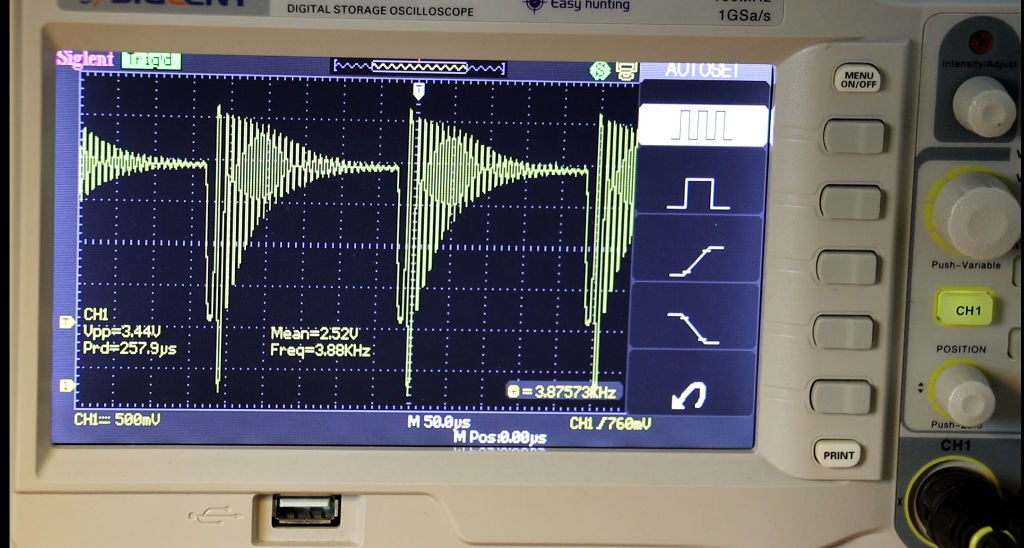

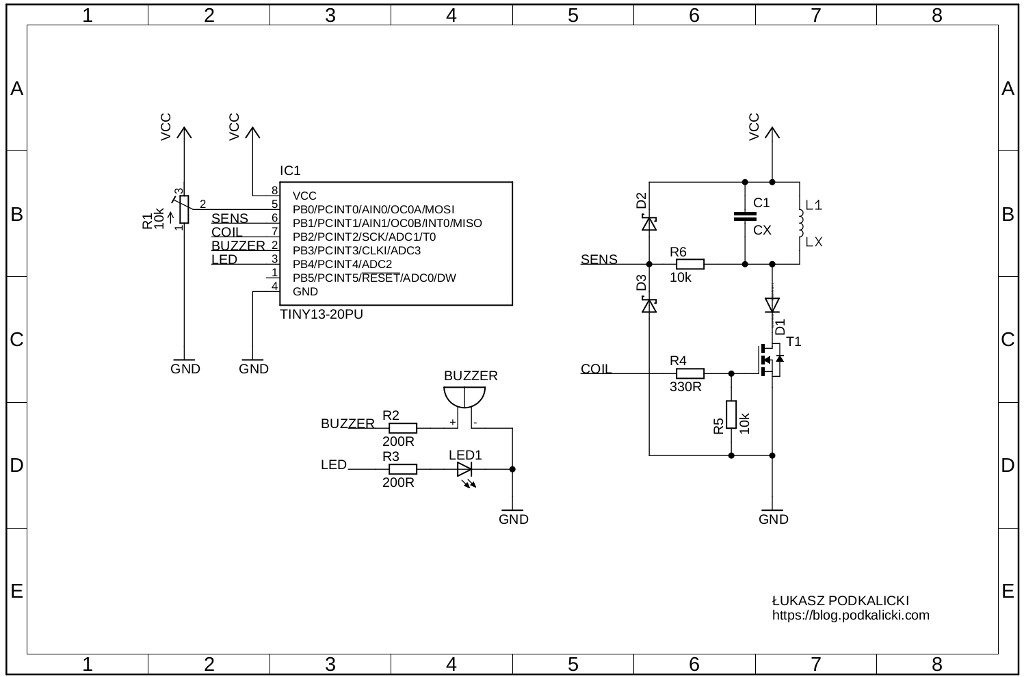

Presented metal detector uses PI method to generate a voltage spike in a search coil connected in parallel with capacitor. Next, ATtiny13 uses an Analog Comparator to measure a decay time to zero of resonant circuit. When a metal object nears the loop it will decrease time it takes for the pulse to decay to zero. The change in the width of resonance time is measured to signal the presence of a metal target.

Note that the typical PI detector designs avoid resonant circuit and the measured factor is slightly different!

User Instructions

- Turn on the device. The calibration process takes about second and ends with buzzer signal.

- Use variable resistor to adjust detector sensitivity (you can find it somewhere between a continuous buzzer signal and complete silent).

- The device is ready to work!

Parts Required

- ATtiny13 – i.e. MBAVR-1 development board

- T1 – IRF3205 (MOSFET; N-Channel)

- LED1 – basic LED

- D1 – i.e. 1N4007

- D2, D3 – 1N4148

- R1 – variable resistor 10kΩ

- R2, R3 – 220Ω (5%), see LED Resistor Calculator

- R4 – 330Ω (5%)

- R5, R6 – 10kΩ (5%)

- C1 – 470nF

- L1 – ∅ 50-55mm, about 30 turns of 0.5 DNE

Circuit Diagram

Software

This code is written in C and can be compiled using the avr-gcc. All information about how to compile this project is here.

/**

* Copyright (c) 2019, Łukasz Marcin Podkalicki <lpodkalicki@gmail.com>

* ATtiny13/037

* Example of simple PI (Pulse Induction) metal detector.

*/

#include <avr/io.h>

#include <util/delay.h>

#include <avr/interrupt.h>

#define COIL_PIN PB2

#define BUZZER_PIN PB3

#define LED_PIN PB4

#define PULSE_WIDTH (32) // microseconds

#define CALIBRATION_ATTEMPTS_MAX (128)

#define MEASUREMENT_ATTEMPTS_MAX (2048)

#define SIGNAL_ON() (PORTB |= _BV(LED_PIN)|_BV(BUZZER_PIN))

#define SIGNAL_OFF() (PORTB &= ~(_BV(LED_PIN)|_BV(BUZZER_PIN)))

static uint16_t

measure_decay(void)

{

uint16_t i, counter = 0, decay = 0;

PORTB |= _BV(COIL_PIN); // pulse on

_delay_us(PULSE_WIDTH); // pulse delay

PORTB &= ~_BV(COIL_PIN); // pulse off

for (i = 0; i < MEASUREMENT_ATTEMPTS_MAX; ++i) {

if (ACSR & _BV(ACO)) {

decay = counter;

}

counter++;

}

return decay;

}

static uint16_t

calibration(void)

{

uint8_t i;

uint16_t tmp, decay = 0;

/* calibration process */

for (i = 0; i < CALIBRATION_ATTEMPTS_MAX; ++i) {

tmp = measure_decay();

if (tmp > decay) {

decay = tmp;

}

}

/* signalize end of calibration */

for (i = 0; i < 3; ++i) {

for (tmp = 0; tmp < 64; ++tmp) {

SIGNAL_ON();

_delay_ms(0.3);

SIGNAL_OFF();

_delay_ms(0.3);

}

_delay_ms(64);

}

return decay;

}

int

main(void)

{

uint16_t decay_cur, decay_max;

/* setup */

DDRB = _BV(COIL_PIN)|_BV(LED_PIN)|_BV(BUZZER_PIN); // set COIL, LED and BUZZER pins as output

ACSR = 0; // clear register

decay_max = calibration() - 1;

_delay_ms(500);

/* loop */

while (1) {

decay_cur = measure_decay();

if (decay_cur < decay_max) {

SIGNAL_ON();

_delay_us(100);

}

SIGNAL_OFF();

}

}

Hello Lukasz, thanks for the project! There is one thing I don’t understand to in the circuit – what are the D2 and D3 diodes good for? I’d assume they could be handy as a voltage regulator for the SENS output signal. But I don’t see how that type in that configuration could help with that. Also when I put the circuit together, they don’t seem to clamp the signal.

fajny, ale znając życie zapewne nie znajdzie złotej obrączki i na złoto ślepy jak kret – jako puls induction. 100hz 😉

Stanowczo. Ten projekt jest taką propozycją do zabawy i eksperymentów z wykrywaniem metali 🙂

Ahoj prosím ťa mohol by si mi poslať hex súbor.

Ďakujem

S pozdravom

Laco

Witam

Spodobał mi się ten detektor metali.

Robię taki dla siebie i syna.

Mam wszystkie części.

Problem to zaprogramowany układ.

Można taki z softem gdzieś kupić.

Proszę o info.

Pozdrawiam

Zrobiłem to urządzenie, ale z jakiegoś powodu działa bardzo cicho. I bez względu na obecność tranzystora 🙁 Metal wykrywa (szczypce – 5 cm.). Powiedz mi, gdzie mam szukać problemu? 🙂

Zgaduje, że kiepski buzzer użyłeś (albo z generatorem, w tym projekcie powinien być bez generatora). Ten piezzo co ja używałem, po wielu próbach, mimo iż minęło wiele miesiący od tego czasu, nadal mi dzwoni w uszach 😉

WinAVR is a severe pain in the ass!

Why can’t you just post a compiled .hex file here? I would be happy to have it! Thanks!

Hi Łukasz

Very nice! I was wondering : wouldn’t it be more sensitive measuring the shift in frequency instead of shift in decay time (i.e. resonance position instead of resonance width) ?

Hi lukasz … can u upload the hex code here ?

I made the metal detector but it dosnt sens any metal object

This looks like a funny and interesting experiment. Why did u choose to program in C language?

I tried to compile this code in the AVR sketch but it gives me an error code.

uint16_t measure_decay() ‘ was declared ‘extern’ and later ‘static’ [-fpermissive]

Where did I go wrong?

Hi, I dont know what require AVR sketch to build this project but you can be sure that avr-gcc compiles it well.

You say to use coil wire 0.5DNE

What does DNE mean?

I only know AWG or SWG wire.

Thanks

Chris, its simply Cu wire like that one used it DC/AC motors with 0.5mm diameter.

Have you tried any of those experiments with higher supply voltage/larger coil? I’m interested in using this to detect nails and similar in wood that I’m salvaging, to spare the cutting blades from damage.

I have tested it with 5V supply and longer pulse (~100us). The device consumes more current but gives better results with the same coil. I think, it should detect the nails in wooden plank.

How small a metal item can this detect at 5cm? I often lose a small screw on the floor and this could help.

The coil I presented here doesn’t detect a smaller screws then M4. There is a space for experiments with bigger coil and higher power supply (5V) to get better range/params.